Clean carbon dioxide foam fracturing fluid SU-CFF

Basic Composition:

To achieve compatibility ,We highly recommended using our own products as additives.

Additives contained

| Addditives |

Function |

Concentration |

| BCG-8 |

Thickener |

0.35%-0.60%(w/v) |

| B-55 |

Synergist |

0.25%-0.60%(w/v) |

| GBS-18 |

surfactant |

0.20%-0.30%(w/v) |

| FBG-12 |

gel breaker |

0.01%-0.20%(w/v) |

| FPC-16 |

pH control agent

|

0.10%-0.20%(w/v) |

Description:

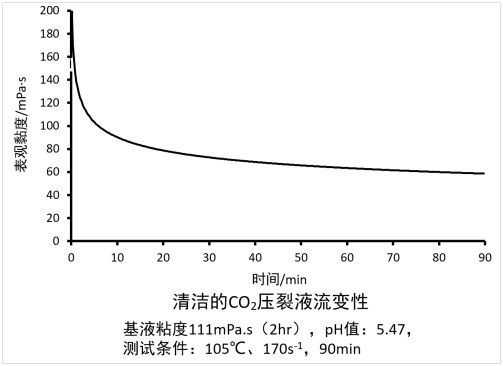

The fracturing fluid uses BCG-8, an improved version of BCG-1, as the fracturing fluid thickener. It has strong viscosification ability and can dissolve in water to form colloidal solution in low pH environment. It can cooperate with the additive B-55 to form a strong spatial structure, so that the solution has a strong viscoelasticity. The gel is compatible with carbon dioxide, allowing the gel to form a foam with carbon dioxide, greatly improving foam stability. There is no residue after liquid phase breaking, which is conducive to the transformation of low permeability, water sensitive, water locked and fractured reservoirs.

Product Characteristics:

1: The product has all the properties of foam fracturing fluid;

2: An aqueous solution that can be dissolved at low pH (pH=5.0~7.0) to form a fracturing fluid base fluid;

3: It can be combined with other functional additives to form a high viscoelastic gel under low pH (pH=5.0~7.0) conditions, which can be used as a sand-carrying fluid in fracturing construction;

4: The gel can form foam with carbon dioxide, which is used for carbon dioxide foam fracturing;

5: The liquid phase of foam fracturing fluid does not contain polysaccharides, and will not breed bacteria in the ground and formations. This prevents fracturing fluids from biodegrading or clogging formations with biogels, reducing fracture conductivity;

6: Water dilution, organic matter addition, and oxidation will cause the fracturing fluid to rupture;

7: The gas-liquid phase of the foam fracturing fluid does not contain residues, and the residue content after crushing is low, and the conductivity damage is generally less than 10%;

8: This product is especially suitable for fracturing operations in ultra-low permeability, water-sensitive, water-locked, fractured oil and gas reservoirs.

Company Service:

Our professional technical service team has long been engaged in oil reservoir stimulation, oilfield chemical additive research and technical services.

Since 2000, the team has been working on the research of a new generation of fracturing fluids and has made new achievements. In 2005, the pilot construction was carried out, which achieved phased results and achieved good production increase results.

At present, new fracturing fluids are being developed and upgraded continuously, and various technical indicators are rapidly improving.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!